Hobaneng U Khetha Tšebeletso ea Fanchi Sheet Metal Fabrication

Tlhaloso

Litšebeletso tsa ho etsa lesela la tšepe la Fanchi ke tharollo e theko e tlaase, e batloang ke litlhoko tsa hau tsa tlhahiso.Litšebeletso tsa rona tsa ho etsa lihlahisoa li tloha ho li-prototype tse tlaase ho ea ho lihlahisoa tse phahameng tsa tlhahiso.U ka fana ka litšoantšo tsa hau tsa 2D kapa 3D ho fumana mantsoe a qotsitsoeng hang hang.Re tseba lipalo tsa lebelo;ke ka lebaka leo re fanang ka qotso hang-hang le linako tse etellang pele ka potlako likarolong tsa hau tsa tšepe.

Litheko tsa tlhōlisano

Rea tseba hore u tlameha ho boloka morero oa hau o le ka har'a tekanyetso.Sebopeho sa rona sa tlholisano sa litheko se etselitsoe hore se khonehe bakeng sa lik'hamphani tsa boholo bohle tse nang le lisebelisoa tse fokolang kapa tse se nang tsona.

Tlhahiso ka Nako

Matsatsi a hau a nako a bohlokoa joalo ka a rona.Re theha puisano e bulehileng le tlhahiso ea odara ea hau ka nako, kahoo o tseba hantle hore na o ka lebella likarolo tsa hau neng.

Tšebeletso e Phahameng ea Bareki

Baenjineri ba rona ba nang le boiphihlelo le litsebi ba teng ho araba lipotso tsa hau le ho fana ka litšebeletso tse ikhethileng ho u thusa ho netefatsa hore u fumana likarolo tse nepahetseng bakeng sa litlhoko tsa hau.

Botšepehi le Boitsebelo

Re motlotlo ho fana ka ts'ebeletso e tšepahalang, ea boleng boo u ka tšepang hore e tla fihlela litlhoko tsa hau nako le nako.

Likarolo tse nepahetseng tsa tlhahiso li sebetsa tse kholo le tse nyane

Sehlopha sa rona se na le tsebo e ngata ho thekenoloji ea indasteri e lumellang ho fetoha ha maemo ho latela maemo a projeke a boletsoeng esale pele.

Kamoo Sheet Metal Fabrication e Sebetsang Kateng

Ho na le mekhahlelo e 3 e tloaelehileng ea mokhoa oa ho etsa lesela la tšepe, tseo kaofela li ka phethoang ka mefuta e sa tšoaneng ea lisebelisoa tsa masela.

● Ho Tlosoa ha Lintho: Nakong ena, mosebetsi o tala o khaoloa ho ea sebopeho se batlang.Ho na le mefuta e mengata ea lisebelisoa le mekhoa ea machining e ka tlosa tšepe ho tloha mosebetsing.

● Phetoho ea lintho tse bonahalang (ho etsa): Karolo ea tšepe e tala e kobehile kapa e etsoa sebopeho sa 3D ntle le ho tlosa thepa leha e le efe.Ho na le mefuta e mengata ea lits'ebetso tse ka bopang workpiece.

● Ho kopanya: Sehlahisoa se phethiloeng se ka kopanngoa ho tsoa ho li-workpieces tse 'maloa tse entsoeng.

● Mehaho e mengata le eona e fana ka litšebeletso tsa ho qetela.Hangata mekhoa ea ho qetela e hlokahala pele sehlahisoa se entsoeng ka tšepe se se se loketse ho rekisoa.

Melemo ea Sheet Metal Fabrication

● Ho tšoarella nako e telele

Joalo ka machining a CNC, lits'ebetso tsa tšepe tsa sheet li hlahisa likarolo tse tšoarellang hantle tse loketseng li-prototypes tse sebetsang le tlhahiso ea ts'ebeliso ea ho qetela.

● Khetho ea Lintho

Khetha ho tsoa mefuteng e fapaneng ea lirafshoa tsa lishiti ho pholletsa le matla a fapaneng, conductivity, boima ba 'mele, le tse thibelang kutu.

● Ho Fetoha ka Potlako

Ho kopanya ho itšeha, ho kobeha le ho phunya morao-rao ka theknoloji e ikemetseng, Fanchi e fana ka mantsoe a qotsitsoeng hanghang le likarolo tse phethiloeng matsatsing a 12 a khoebo.

● Scalability

Likarolo tsohle tsa tšepe li hahiloe ho latela tlhoko le ka litšenyehelo tse tlase tsa ho seta ha li bapisoa le CNC Machining.Ho ipapisitse le litlhoko tsa hau, odara hanyane joalo ka prototype e le 'ngoe ho fihlela likarolo tse 10,000 tsa tlhahiso.

● Liphello Tse Tloaelehileng

Khetha ho tsoa mefuteng e fapaneng, ho kenyelletsa anodizing, plating, ho roala phofo le ho penta.

Leqephe la Metal Fabrication Process

Tšebeletso ea ho khaola Laser

Tšebeletso ea ho Koba

Tšebeletso ea Welding

Lisebelisuoa tse Tloaelehileng tsa Letlapa la Metal

| Aluminium | Koporo | Tšepe |

| Aaluminium 5052 | Koporo 101 | Sebetsa 301 |

| Aluminium 6061 | Koporo 260 (Koporo) | Sebetsa 304 |

| Koporo C110 | Tšepe e se nang Mokelikeli 316/316L | |

| Tšepe, Khabone e Tlase |

Likopo tsa ho Fetola Metal

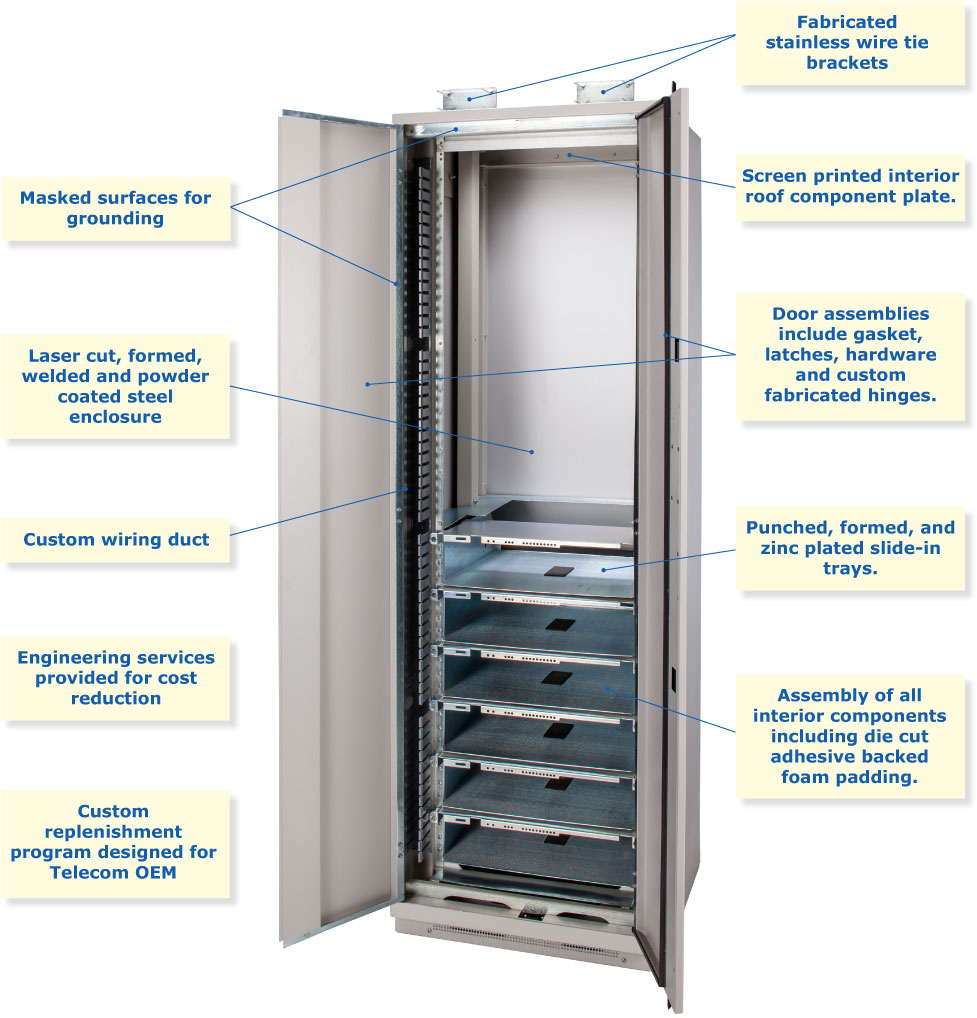

Libaka tse koaletsoeng- Sheet metal e fana ka mokhoa o theko e boima oa ho etsa liphanele tsa lisebelisoa tsa sehlahisoa, mabokose le likhese bakeng sa lits'ebetso tse fapaneng.Re haha mehaho ea mefuta eohle, ho kenyelletsa li-rackmounts, libopeho tsa "U" le "L", hammoho le li-consoles le li-consolets.

Chassis- Chassis eo re e etsang hangata e sebelisoa ho boloka li-electromechanical controls, ho tloha ho lisebelisoa tse nyane tse tšoaroang ka letsoho ho isa ho lisebelisoa tse kholo tsa tlhahlobo ea indasteri.Li-chassis tsohle li hahiloe ka litekanyo tsa bohlokoa ho netefatsa hore ho na le mokhoa oa ho tsamaisana le likarolo tse fapaneng.

Masakana-FANCHI e etsa li-brackets tse tloaelehileng le likarolo tse ling tsa tšepe tse fapaneng, tse loketseng hantle bakeng sa lisebelisoa tse bobebe kapa ha ho hlokahala hore ho se ke ha e-ba le kutu.Lisebelisoa tsohle le li-fasteners tse hlokahalang li ka hahoa ka ho feletseng.